We went on a factory tour to Kaneko Kohyo Pottery, a ceramics manufacturer in Toki-shi, Gifu Prefecture!

In this article, we will introduce Kaneko Kohyo Pottery in detail along with the manufacturing process of “Rinka”.

About “Rinka”

The “Rinka” series made by Kaneko Kohyo Pottery.

It is characterized by a design that has the atmosphere of an antique item, but at the same time has a somewhat modern feel.

Like a flower blooming on the table, it adds a splash of color to the dining table. It is very beautiful!

About Kaneko Kohyo Pottery

Kaneko Kohyo Pottery is a Mino ware manufacturer located in Shimoishi-cho, Toki-shi, Gifu Prefecture.

This year (2021) marks the 100th anniversary of its founding.

Tour of Kaneko Kohyo Pottery begins

This time, we will visit Kaneko Kohyo Pottery along the process of making rinka.

The factory is bright, clean and tidy.

This is where the linker is made.

This is a pre-fired rinka.

It looks a little darker because there is still some moisture in it.

Yuki Ito gives a detailed explanation. (Left)

Thank you very much. (Right: Kogiso)

Mr. Ito also operates a You Tube channel.

He introduces Mino ware from various angles, and it is very informative!

After baking, the moisture is removed and the dough becomes pink.

This is the process of making a mark on the back side of a vessel.

The backside is marked by a method called pad printing.

Edge processing process. Each piece is carefully processed one by one.

This process is used to adjust the coloring and express the unique atmosphere of the Rinka.

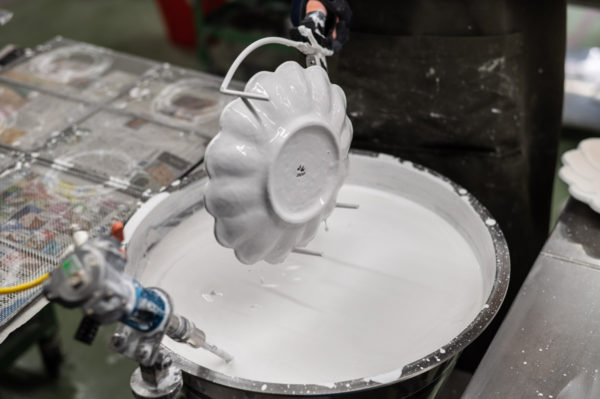

Glazing process.

This process is very dynamic.

It is a delicate process that requires the experience and intuition of the craftsman.

Finally, the final firing takes place in the kiln.

Kaneko Kohyo Pottery uses a method called reduction firing.

The vessels are finished after about 20 hours of firing.

Thus the Rinka is completed.

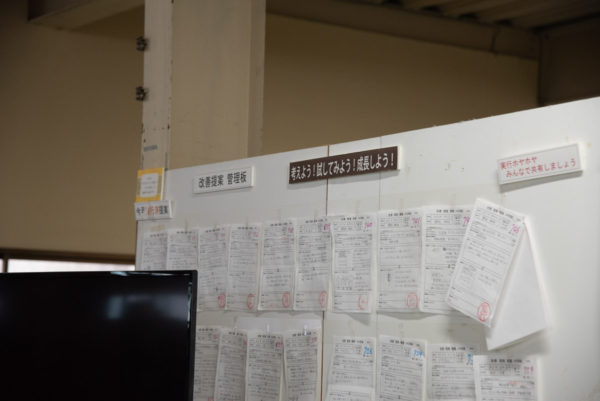

While touring the factory, I noticed many things.

Anyway, there were various “innovations” in the factory everywhere of Kaneko Kohyo Pottery!

And…

↑upThis is the “Little Happiness” tree.

This one really inspired me!

During the morning meeting, the employees who work in the factory make a presentation about the “small happiness” they have found recently.

I think this is a good communication tool for the workers, and it naturally leads to the desire of the makers to deliver such “small happiness” to the customers as well.

It was really a very educational experience for me.

The origin and philosophy of “Rinka”

We interviewed Mr. Katsunori Ito, president of Kaneko Kohyo Pottery.

Originally, Kaneko Kohyo Pottery was mainly engaged in making tokkuri (sake cups), which flourished in the Dachi district of Toki City, Gifu Prefecture.

We wanted to create something that could be used as much as possible by people who actually use tableware often in their daily lives!

That is how Rinka was born.

Durable and easy to wash

The more luxurious a vessel is, the more care is taken when washing it.

I want to overturn this notion!

Let’s challenge ourselves to see how far we can go in expressing the handmade clay-like feel of porcelain with its durability and ease of washing! The production started with this idea from the president.

The president’s junior at school is a moldmaker who makes prototypes of vessels out of clay, and when we approached him, he too agreed with the concept of the Kaneko Kohyo Pottery.

Normally, prototypes are made with plaster, but for Rinka, the moldmaker makes prototypes with clay.

He said that he might be the only person in Mino ware who can make prototypes with clay.

The “chrysanthemum-shaped” design has long been in the president’s heart, and after much trial and error with a mold maker, he devised a mold that would make the edges of the tableware thicker and less likely to chip, yet lighter….

The shape is also derived from nature.

The shapes are also derived from nature, and we tried to express the texture by pressing natural stones and other materials on them.

However, porcelain has a shrinkage rate of about 15% before and after firing, and the shrinkage process also causes deformation.

We had to make many revisions to create a single mold, and somehow we managed to increase the number of shapes.

The shape ideas are not limited to the president and the moldmaker, but also incorporate the opinions of the president’s wife, employees, and many others who actually use the tableware in their daily lives. (Many of the people who work at Kaneko Kohyo Pottery also love tableware.)

The president of Kaneko Kohyo Pottery and everyone at Kaneko Kohyo Seisakusho’s desire to create products that can be incorporated into daily life is strongly reflected in the vessels.

The president also says, “The vessel is only a supporting role.”

I wanted to create something that would only become a world view when you put a dish on it.

The presence of the dish makes you want to cook with it.

We want you to actually “use”, “cook”, “eat”, and “talk” with us…

Even the usual menu items are not enough to make you say, “Oh! What’s on the menu today?”

and conversation naturally ensues….

The dishes were created with such “small moments of happiness” in mind for the people who actually use them.

…Speaking of which, I just discovered “Kohyo’s ‘Small Happiness’ Tree” during a tour of the factory.

I believe that the “Small Happiness Tree” is also an initiative born from the philosophy of Kaneko Kohyo Seisakusho.

The production process is also available on Mr. Ito’s You Tube channel, Kaneko Kohyo Pottery, so be sure to check it out!

リンク:

(Thank you very much for your cooperation to Kaneko Kohyo Pottery.)

Introduction of Utsuwa

Click here to see the Rinka series by Kaneko Kohyo Pottery, which we visited this time.

There are many different Linka series, but here is my top pick.

RINKA 10cm bowl “Momoneri”.

I like the tripod shape.

A convenient 17cm dish that can be used in a variety of ways.

Soup cups are also popular.

A large plate that I definitely want.

コメント